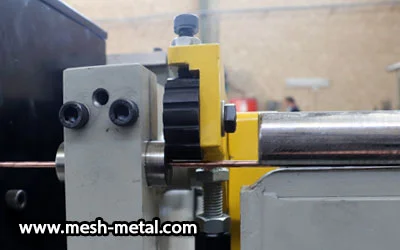

Wire mesh straightener is used to extend wires from a roll or a coil in order to straight and to cut for all kinds of smooth and ribbed wires. This machine has three different process, e.g. feeding, straightening and cutting off.

The wire straightener and cutter is easy to operate. One just needs to fix the adjuster to the desired length, followed by feeding the wire into the machine. Afterwards, the machine produces straight wire at a high speed automatically. All the production procedure is noiseless, which is the most important advantage of a Metal Mesh Wire Straightening and Cutting Machine.

| Technical Details of Wire Straightening and Cutting Machine | |

|---|---|

| Length of wire to be cut automatically | 100mm to 6000mm Length can be increased as per your Requirement |

| Thickness of wire | 3mm to 8mm |

| Number of tension gearboxes | 2 |

| Capacity per min | 25(m/min) – 60 (m/min) |

| Required R.P.M | Inverter speed 1500rpm-4500rpm |

| Wire Type | Stainless steel, Copper, Brass and Aluminium wire |

| Cutting system | Hydraulic |

Wire Straightening and Cutting Machine’s features:

- All machines come with a 1‑year guarantee on Electronic components.

- Has a system of PLC length adjustment for precise control of the production process.

- It has a smart stop safety system.

- It has a counter system and automatic switch off.

- Fast Feeding

- Cutting tools has a simple construction, easy to adjust and change

- Has the ability to plan

- Supports wires with different diameter for straightening

- Supports different cutting lengths

- Has a standard multi-power motor for both straightening and cutting of wires

Performance of Wire Straightening and Cutting Machine:

First, the wire coil is placed on the paying off unit. Then, the wire passes through the tension rollers. The rollers pull the wire from the coil and insert it into the rotating spinner. Again the tension roller pull the wire from spinner and push it in to cutter nozzle. Then guide bar where an adjustable spring loaded stopper which can be adjusted -depending on the rod length required. When the wire reaches the desired length, it is detected by a sensor. Then the wire stops moving. The cutter, which moves with hydraulic force, cuts the wire at this stage.